Large Tempered Moulding Tools (TemGro)

Object of research

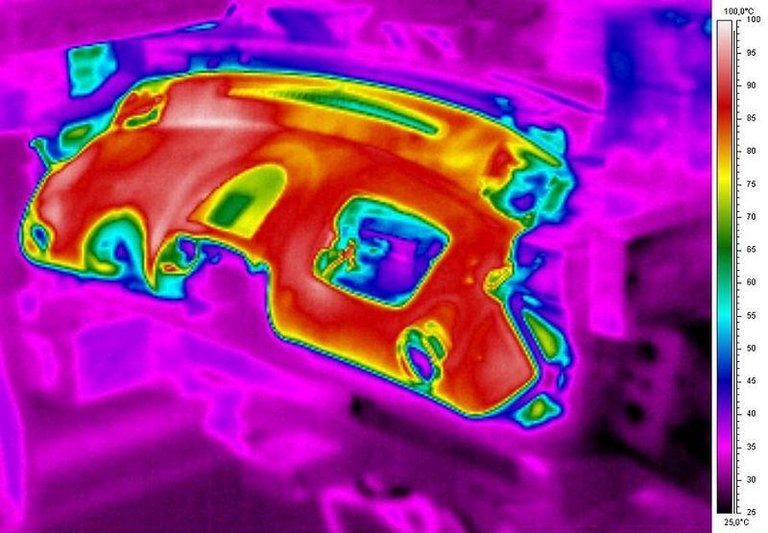

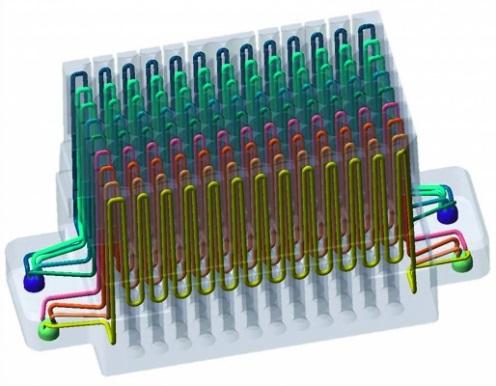

- The generation of a near-contour temperature control

- The design of large-format moulds (bumper, container, etc.) with near-surface cooling channels by combining the additive manufacturing processes arc welding and diffusion welding with conventional processes

- These are moulds intended for injection moulding, pressure die casting, punching, reforming and press hardening

Results

- Development of methods and strategies for the construction of large-dimension moulds with inside-recumbent cooling channels

- Provision of the proof of functionality

- Comparison of conventionally manufactured tools with the additively manufactured tools in respect of cycle time and warpage

Institutes involved and contact details

Schmalkalden University of Applied Sciences

Faculty of Mechanical Engineering

Manufacturing Engineering/Tool Design

Prof. Dr.-Ing. Thomas Seul

E-mail: t.seul@hs-sm.de

Phone: 03683 688 1004

Technical University of Ilmenau

Faculty of Mechanical Engineering

Department of Manufacturing Engineering

Univ-Prof. Dr.-Ing. habil. Jean Pierre Bergmann

Günther-Köhler-Institut für Fügetechnik und Werkstoffprüfung GmbH

Otto-Schott-Str. 13

07745 Jena

Dr.-Ing. Simon Jahn

Third-party funds provider

Guideline on Subsidies for Personnel Working in Research and Development / Research Groups (FGR) of Thüringer Aufbaubank (TAB)

Additional information

- Period: - 10/2016 – 09/2019 (36 months)

- Funding amount: € 696,717.01

- pdf: TemGro - Large Tempered Moulding Tools

- pdf (german): TemGro - Temperierte Großwerkzeuge