WASABI

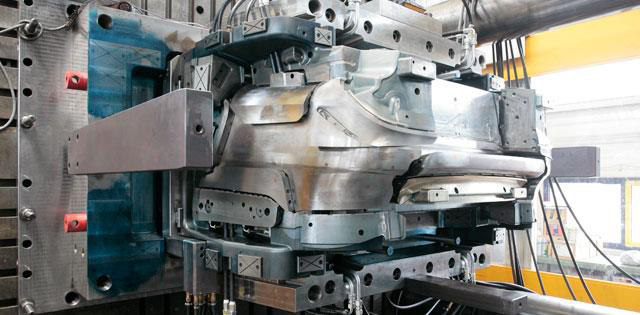

"Tools-integrated assistance system for production control in injection moulding of highly complex and demanding component specifications

Problem Statement

- Permanent operating point monitoring

- In situ quality control

- Efficient process adaptations

- Loss of knowledge on start-stop production processes due to the elimination of co-workers

- Avoidance of rejects and downtimes

Approach to Solution

- Implementation of sensors in injection moulds

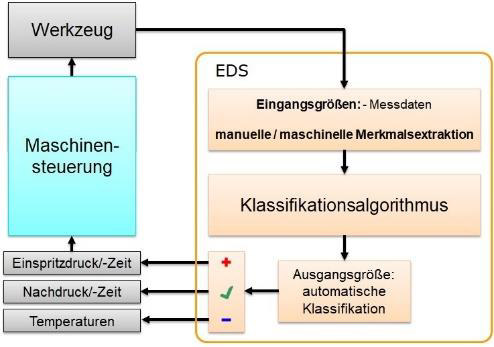

- Combination of OptiCheck and EDS sensor signals

- Hardware and software development for the application of machine learning methods

- Integration and improvement of classification algorithms

Target

Realization of a digital assistance system for production optimization in plastic injection moulding.

Project Partners

University of Applied Sciences Schmalkalden

Faculty of Mechanical Engineering

Applied Plastics Technology

Prof. Dr.-Ing. Thomas Seul

Contact: t.seul@hs-sm.de

Schneider Form GmbH

department OptiCheck

project manager Mr. Markus Lehr

Contact: schneider-form.de/kontakt

Project Sponsors / Third-Party Donor

- Karlsruhe Institute of Technology (KIT)

- Federal Ministry of Education and Research (BMBF)

Additional information

- Grant Sum: 550,000.- €

- Duration of Project: 06/2019 - 05/2021

- pdf: WASABI - Tools-integrated assistance system for production control in injection moulding of highly complex and demanding component specifications

- pdf (german): WASABI - Werkzeugintegriertes Assistenzsystem zur Produktionsregelung beim Spritzgießen hochkomplexer und anspruchsvoller Bauteilspezifikationen