Forschungsprojekt Extrusionswerkzeuge auf Basis von Additiv Manufacturing (ExAM)

Research project on extrusion tools based on additive manufacturing

Subject of research

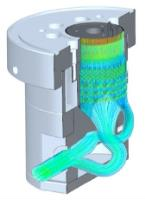

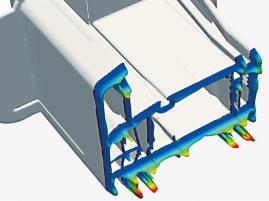

- Extrusion Tools Based on Additive Manufacturing – ExAM

- Performance Enhancement of Extrusion Tools through Optimal Design of Tool Geometry Using Additive Manufacturing Technologies

- Development of a Systematic Design Methodology for Extrusion Tools Using the Additive Manufacturing Process Chain

Results

- Guideline for the Systematic Design Methodology of Extrusion Tools Using the Additive Manufacturing Process Chain

- Potential Enhancement for the Optimization of Extrusion Tools

- Knowledge Transfer in Tool and Mould Construction

Project partners

Schmalkalden University of Applied Sciences

Faculty of Mechanical Engineering

Product Development/Design

Prof. Dr.-Ing. Stefan Roth

www.angewandte-kunststofftechnik.de

University of Paderborn

Faculty of Mechanical Engineering

Plastics Processing

Prof. Dr.-Ing. Volker Schöppner

www.ktp.uni-paderborn.de

Fraunhofer Institute for Additive Production Technologies

M.Sc. Katharina Bartsch

www.iapt.fraunhofer.de

Third-party funder

Deutsches Zentrum für Luft- und Raumfahrt e. V.

im Auftrag des Bundesministeriums für Wirtschaft und Klima (BMWK)

aus Mitteln der Industriellen Gemeinschaftsforschung (IGF)

Additional information

- Run time: 08/2024 - 07/2026 (24 Monate)

- Project volume: 164.919,51 €

- Funding reference number: 01 IF 23360N

- pdf (german): ExAM - Extrusionswerkzeuge auf Basis von Additiv Manufacturing