Project SMoSys

Cutting-monitoring-system for self-propelled forage harvesters

Problem Statement / Approach to Solution

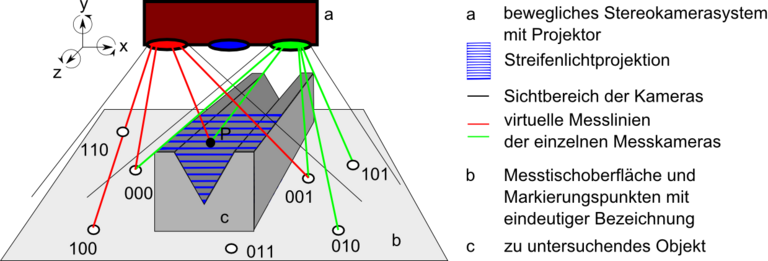

Modern self-propelled forage harvesters are equipped with various assistance systems for smooth operation. These include sensors and electronics, which are used, for example, to adjust the cutting gap. In order to ensure a constant quality of the cutting process, the driver needs a robust determination of the wear of the cutting edges. The goal of the project is to develop and construct a grinding assistance system, which enables an automatic evaluation of the degree of wear of the knives based on acoustic signals. The basis is formed by findings from the predecessor project "EMiL" as well as current results from test bench tests, field tests, optical measurement of the cutting geometry with machine evaluation and image analysis of shredded material samples.

Project manager

University of Schmalkalden

Faculty of Electrical Engineering

Blechhammer 9

D-98574 Schmalkalden

Prof. Dr.-Ing. Andreas Wenzel

Phone: +49 (0) 3683 688 5113

a.wenzel@hs-sm.de

M.Sc. Manuel Schneider

Phone: +49 (0) 3683 688 5216

m.schneider@hs-sm.de

Project Partners

University of Kassel

Ecological Agricultural Science

Department of Agricultural Engineering

Georg-August-Universität Göttingen

Crop Science

Department of Agricultural Engineering

CLAAS

Self-propelled harvesting machines GmbH

Project Sponsors

Landwirtschaftliche Rentenbank German Innovation Partnership Agriculture (DIP Agrar)

Additional information

- Projekt duration: 09/2017 – 09/2020

- Supported by funds from the special-purpose assets of the Federal Government:

- Project volume: 254,471.24 €

- Application number: 836 594

- pdf: SMoSys - Cutting-monitoring-system for self-propelled forage harvesters

- pdf (german): SMoSys - Schneid-Monitoring-System für selbstfahrende Feldhäcksler