NextMould

Collective Research Networking – Cornet

Research topic

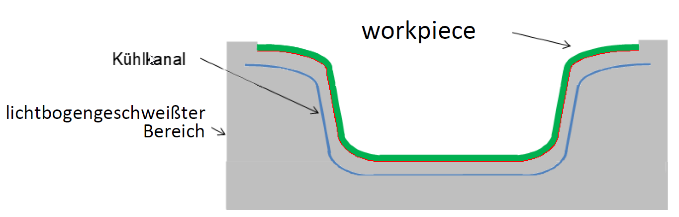

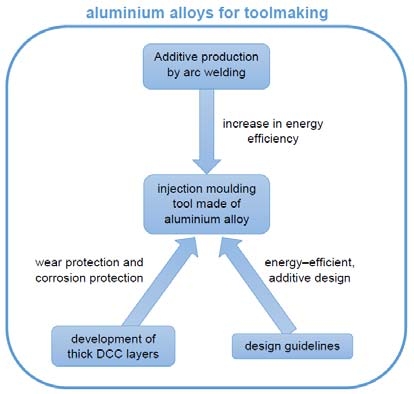

Development of hybrid energy-efficient aluminum injection moulding tools through electric arc additive and friction stir welding, as well as deposition of thick diamond-like carbon layers.

Results

- Design guideline for the construction of aluminum injection moulding tools

- Additive manufacturing of injection moulding tools out of aluminum through the use of electric arc and friction stir welding

- Embedding of honeycomb and truss structures in the additive manufactured tools

- Development of thick DLC coatings for wear protection

Participating Institutions and Contact Details

University of Schmalkalden

Faculty of Mechanical Engineering

production technology / tool design

Prof. Dr.-Ing. Thomas Seul

E-Mail: t.seul@hs-sm.de

Telephone: 03683 688 1004

Technical University of Ilmenau

Faculty of Mechanical Engineering

FG Production technology

Prof. Dr.-Ing. Habil. Jean Pierre Bergmann

FH Oberösterreich

Franz-Fritsch-Str. 11

4600 Weis

FH-Prof.Dipl.-Ing. Dr. tech. Daniel Heim

Business Upper Austria - Plastics Cluster Oberösterreich

Doris Würzlhuber

FGW - Research Association for Tools and Materials e.V.

Dr. Christian Pelshenke

Third-Party Donors

- AIF – German Federation of Industrial Research Associations / BMWI – Federal Ministry for Economic Affairs and Energy

- FFG – Austrian Research Promotion Agency

Additional information

- Run time: 10/2019 – 09/2021 (24 Month)

- Cost Volumes: - 705,926 € (of which 583,987€ is from subsidies)

- pdf: NextMould - Collective Research Networking – Cornet

- pdf (german): NextMould - Entwicklung von Aluminium-Großserienwerkzeugen durch additives Lichtbogenschweißen und Beschichtungssysteme