Project AlPro

Subject of research

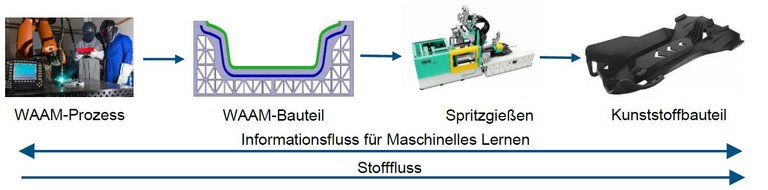

- Smart aluminium injection moulds using WAAM and AI methods for energy-efficient and resource-saving production processes

- Production of components of an injection mould using WAAM

- Production of plastic components using injection moulds that contain the WAAM components

- Analysis and evaluation of the manufactured plastic components (surface structure, tolerance, etc.) and the WAAM components (wear, etc.) after a certain service life of the injection moulding tool using machine learning methods and drawing conclusions about the manufacturing process (WAAM) and its readjustment to improve the component specifications of the WAAM and plastic components for future manufacturing processes.

Results

- Additive manufacturing of functional components for tool and mould making using WAAM

- Saving energy and resources in injection moulding production

- Networking the component properties or predictive maintenance of the injection moulding process with the process parameters of additive manufacturing using machine learning methods

- Increasing the product quality of the plastic component and the injection mould through adapted production processes (WAAM)

Project partners

Hochschule Schmalkalden

Fakultät Maschinenbau

Fertigungstechnik/Werkzeugkonstruktion

Prof. Dr.-Ing. Thomas Seul

www.angewandte-kunststofftechnik.de

Technische Universität Ilmenau

Fakultät Maschinenbau

FG Fertigungstechnik

Third-party funder

Richtlinie zur Förderung der Forschung (FORRichtlinie)

Thüringer Aufbaubank im Auftrag des Freistaates Thüringen

vertreten durch das Thüringer Ministerium für Wirtschaft

Wissenschaft und Digitale Gesellschaft aus Mitteln des Landes Thüringen

Additional information

- Runtime: 10/2021 - 09/2023 (24 Month)

- Project volume: 352.600,00 €

- pdf (german): AlPro: Smarte Aluminium-Spritzgießwerkzeuge mittels WAAM und KI-Methoden für energieeffiziente und ressourcenschonende Produktionsprozesse

Wertschöpfungskette des AlPro Projektes