Project InTrance

Component Marking and Control of the Drive System

Problem / Solution approach

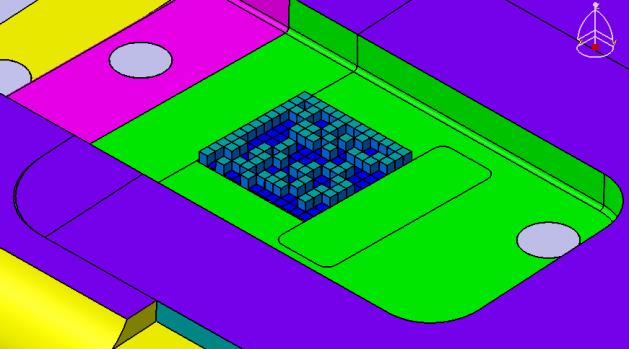

At present, components of injection moulded products are marked in a downstream manufacturing processes. The object of research of this project is the integration of an in‐situ produced individual marking technology. Different marking methods are investigated to apply an individual component marking to the component during the injection moulding process. In this regard, the planned structure is to be similar to a data matrix code or QR code. Other focus areas of the research include thermal simulations, coding of the relevant production data, software development and the integration of a functional pattern into a manufacturing tool.

Project partners

Schmalkalden University of Applied Sciences

Faculty of Mechanical Engineering

Applied Plastics Technology

Prof. Dr.‐Ing. T. Seul Faculty of Electrical Engineering

Embedded Diagnostics Systems

Prof. Dr.‐Ing. A. Wenzel

Formconsult Werkzeugbau GmbH

Dipl.‐Ing. (FH) S. Hoffmann

Additional information

- Project duration: 08/2016 – 07/2018

- Financed with funds from the Central SME Innovation Programme (ZIM)

- Project volume: €190,000.00

- Funding reference number: 16KN045841

- Project sponsor of the BMWi VDI / VDE / IT

- pdf: InTrance - Component Marking and Control of the Drive System

- pdf (german): InTrance - Bauteilmarkierung sowie Ansteuerung des Antriebsystems